Happy Thursday, Friends! I just finished writing a different blog post for TGIFF (Thank Goodness It's Finished Friday) that I've scheduled to publish automatically at 6 PM EST this evening, since that's when Friday begins for those linking up from Australia, so be sure to check back for that one and link up your own finishes, even if it's a small finish like a single block completed. Meanwhile, I have a couple of extra-special client quilts that I've been wanting to share with you.

Julie's Vintage Equestrian Applique Quilt Repair

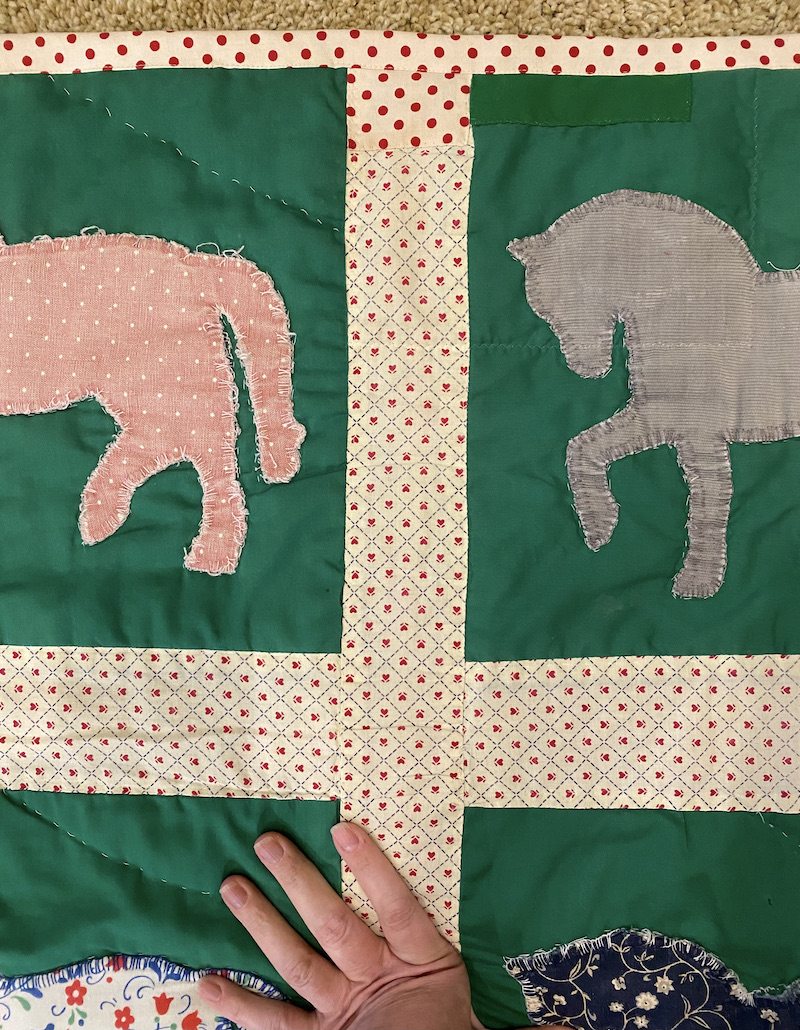

This first one belongs to Julie, whose puppy chewed a hole through all layers of the quilt at the top edge. These dogs sure do keep me busy, don't they?! I neglected to get a good "before" phot of the entire quilt before I started working on it, but here's what it looked like when it was nearly ready to go home again:

|

| 74 x 84 Vintage Equestrian Applique Quilt, After Repair |

Julie cherishes this quilt because her husband had it custom made for her as a surprise gift many years ago. Their family is involved with equestrian sporting and I believe he may have even drawn the horse silhouette for the applique shapes himself. He found a quilter to make it and was given a shopping list of how much fabric was needed, then went to the fabric store and picked everything out himself -- hence the assortment of calicos, corduroys, and poly blend fabrics in this quilt.

|

| Detail of the Worst Damage Area |

This quilt was made with a wide sashing between the blocks and a narrow, 1/2" finished width outer border in the same fabric that simply wrapped to the back of the quilt and was machine stitched in lieu of traditional binding.

|

| Same Spot On the Quilt, Backing Side |

|

| Repairs Completed, All Machine Stitched |

My client's budget dictated that all of the machine repairs would be machine stitched for this project. The binding was damaged and falling off on all four sides of the quilt and would need to be replaced, and finding a suitable fabric was the biggest challenge. I'd initially told Julie that I'd use a solid red for the binding, but I couldn't bring myself to do it. My goal in restoring a family quilt like this is to have it look as much like it did originally as I possibly can, and although a red binding would look good on the quilt, it would definitely draw your eye and look different to its owners. I could not find anything like the original ivory/red/blue print calico fabric in any of the local quilt shops I visited, but I did find a red and white polka dot fabric. I was able to tone down the bright white background of the new fabric to better match the original fabric by coffee staining it before using it to repair the quilt.